A masonry drill bit is a specialized tool designed to cut through tough, abrasive materials like concrete, brick, stone, and mortar. Unlike standard drill bits used for wood or metal, masonry bits are engineered to withstand extreme friction and impact, making them essential for construction, renovation, and DIY projects involving hard surfaces.

How Masonry Drill Bits Work

Masonry drill bits primarily work by pulverizing the material rather than cleanly cutting it. This is due to the inherent hardness and abrasive nature of masonry. The tip of the bit is designed to chip away at the material, and the flutes (spiral grooves) then efficiently remove the resulting dust and debris from the hole.

For optimal performance, masonry drill bits are frequently used with a hammer drill or rotary hammer drill. These drills provide a dual action: rotational movement combined with a rapid, percussive "hammering" motion. This hammering action drives the bit into the material, breaking it down more effectively and allowing for faster, more efficient drilling than a standard rotary drill could achieve alone.

Key Characteristics and Components

Masonry drill bits are distinguished by several key features:

Tungsten Carbide Tip: The most crucial component is the tip, which is typically made from tungsten carbide. This extremely hard and durable material is brazed onto a steel shank. Tungsten carbide's superior hardness allows it to resist the wear and chipping that would quickly dull a conventional steel drill bit when encountering masonry. For even harder materials like reinforced concrete or granite, some bits may feature diamond-coated tips.

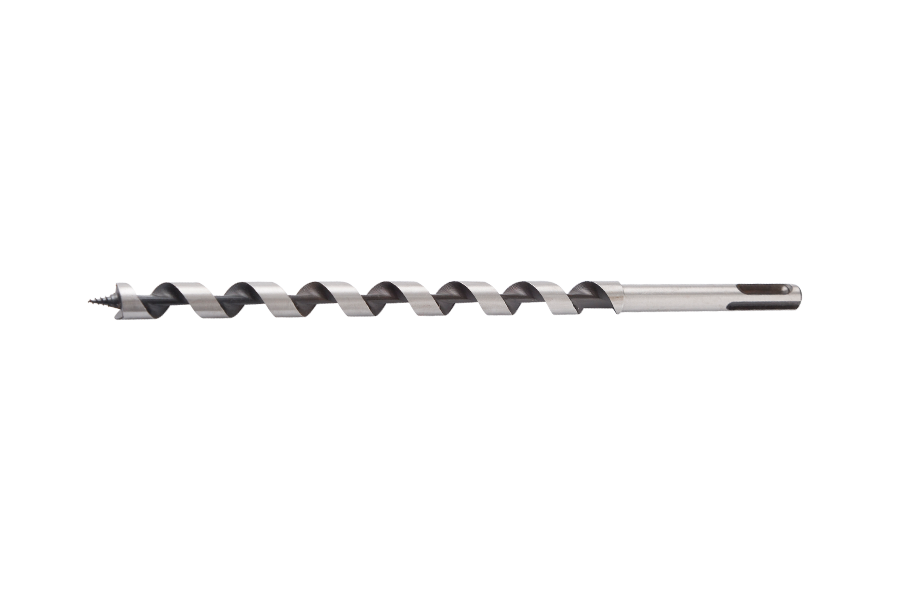

Spiral Flutes: The body of the bit features wide, deep spiral flutes. These flutes play a vital role in clearing the powdered masonry debris out of the hole as drilling progresses. Efficient debris removal prevents clogging, reduces friction, and helps keep the bit from overheating.

Hardened Steel Construction: The main body of the drill bit is made from hardened steel, often High-Speed Steel (HSS) or a tougher steel alloy. This provides the necessary strength and durability to withstand the forces involved in masonry drilling.

Shank Types: Masonry drill bits come with various shank types to fit different drill chucks:

Straight Shank: Common for general-purpose masonry bits.

Hex Shank: Offers better grip in the chuck, reducing slippage.

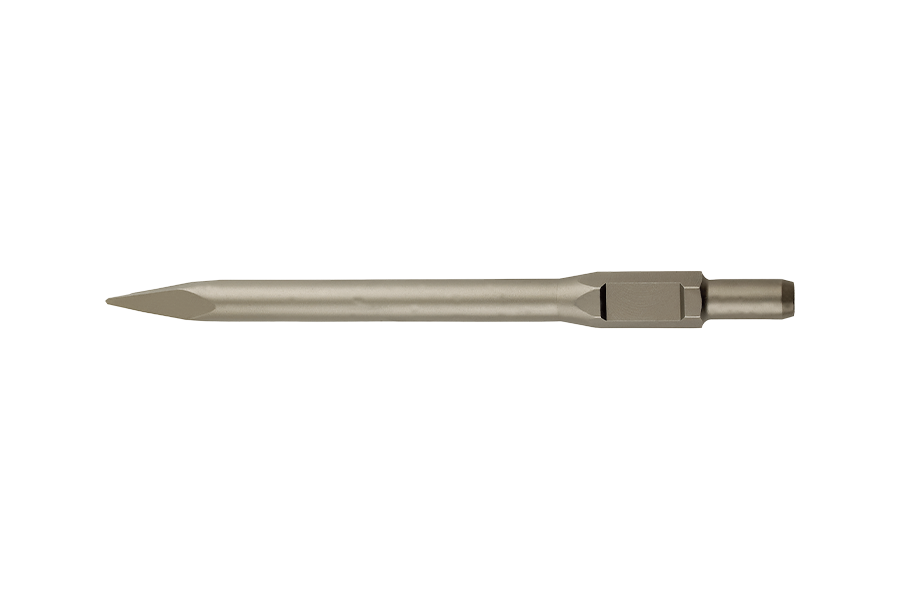

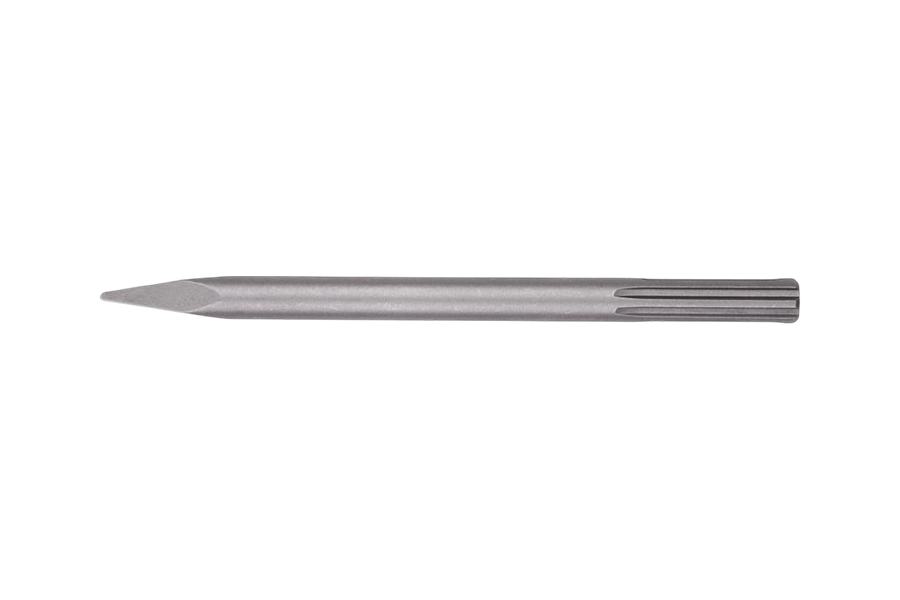

SDS (Slotted Drive System) Shank: Specifically designed for rotary hammer drills. The unique slot system allows the bit to slide within the chuck, facilitating the hammering action and improving power transfer and durability. SDS-Plus and SDS-Max are common variations, with SDS-Max designed for heavier-duty applications and larger hole sizes.

Types of Masonry Drill Bits

While tungsten carbide-tipped bits are the most common, other specialized masonry bits exist:

Carbide-Tipped Drill Bits: The workhorse for most masonry drilling, suitable for brick, concrete, and stone. They are durable and maintain sharpness well.

SDS Drill Bits: Designed for rotary hammer drills, these bits offer enhanced efficiency and durability due to their specialized shank design.

Diamond Core Drill Bits: Used for creating large, clean holes in very hard and abrasive materials like concrete, reinforced concrete, and tiles. These bits often require wet drilling to prevent overheating and typically feature a hollow core.

Percussion Drill Bits: Generally used with hammer drills for softer masonry materials like bricks and aerated concrete. They are less aggressive than SDS bits but still effective for lighter tasks.

When to Use a Masonry Drill Bit

Masonry drill bits are indispensable for any task that involves drilling into:

Concrete (poured, blocks, reinforced)

Brick

Stone (natural and artificial)

Mortar

Tile (specialized tile bits, a subset of masonry bits, are even sharper to prevent chipping)

Common applications include:

Installing anchors and fasteners for shelves, cabinets, or structural elements.

Running plumbing pipes or electrical wiring through walls.

Mounting fixtures or signs on exterior walls.

Demolition or modification of existing masonry structures.

Important Considerations

Drill Type: While a standard drill with a masonry bit can sometimes work for very soft masonry or a few small holes, a hammer drill or rotary hammer drill is highly recommended for any significant masonry drilling. The percussive action dramatically improves speed and efficiency and reduces wear on the bit and the drill.

Drilling Speed: Generally, slower speeds are more effective for drilling into concrete and help prevent the bit from overheating.

Pressure: Apply steady, consistent pressure, but avoid excessive force, which can overheat the bit or cause it to wander.

Debris Removal: Periodically withdraw the drill bit from the hole to allow the flutes to clear debris. This prevents clogging and helps keep the bit cool.

Cooling: For very hard materials or prolonged drilling, especially with diamond bits, wet drilling (using water to cool the bit) can significantly extend the life of the bit and improve performance.

Understanding the unique design and function of masonry drill bits is crucial for achieving successful and efficient results when working with the challenging materials of masonry construction.

English

English

中文简体

中文简体

Español

Español

عربى

عربى