Drill bits are essential tools in countless applications, from home DIY projects to heavy industrial fabrication. Their effectiveness lies in their specialized designs, each tailored for optimal performance on specific materials and tasks. Understanding the various types of drill bits is crucial for achieving clean, precise holes and ensuring the longevity of both the bit and the material being worked on.

General-Purpose Drill Bits

These are the most common drill bits, often found in household drill sets.

Twist Drill Bits

Twist drill bits are characterized by their spiral flutes, which help remove chips from the hole. They are versatile and can be used on a wide range of materials, including wood, plastics, and soft metals. They are typically made from:

-

High-Speed Steel (HSS): Suitable for general drilling in wood, plastics, and softer metals.

-

Cobalt (HSS-Co): HSS bits with an 8% cobalt alloy, offering increased heat resistance and hardness, making them ideal for drilling tougher metals like stainless steel and cast iron.

-

Black Oxide Coated: HSS bits with a black oxide finish that provides some corrosion resistance and reduces friction.

-

Titanium Nitride (TiN) Coated: HSS bits with a thin, hard TiN coating that extends bit life and allows for faster drilling speeds.

Wood Drilling Bits

Wood requires specific bit geometries to prevent splintering and ensure clean entry and exit holes.

Brad-Point Drill Bits

Brad-point drill bits feature a sharp, pointed tip (the brad) and two spurs on the cutting edges. The brad precisely positions the bit, preventing wandering, while the spurs score the wood fibers, creating a clean-cut hole with minimal tear-out. They are excellent for drilling accurate holes in wood, plywood, and MDF.

Spade (Paddle) Bits

Spade bits, also known as paddle bits, have a flat, paddle-shaped head with a sharp point and two cutting spurs. They are used for rapidly drilling large-diameter holes (typically 1/4 inch to 1 1/2 inches) in wood. While fast, they tend to produce rougher holes compared to other wood bits.

Forstner Bits

Forstner bits are designed for creating clean, flat-bottomed holes, overlapping holes, or pocket holes in wood. They have a continuous rim that guides the bit and two cutting edges. They are highly accurate and produce very clean holes, making them ideal for hinge installations and other precision woodworking.

Auger Bits

Auger bits have a large, deep spiral flute and a threaded screw tip that pulls the bit into the wood. They are designed for drilling deep, clean holes in timber, often used in timber framing or for boring through thick beams. The aggressive flute design efficiently clears chips.

Metal Drilling Bits

Drilling metal requires bits that can withstand high temperatures and resist abrasion.

Jobber Length Drill Bits

While not a specific type by design, jobber length drill bits are the most common length for metal drilling. They are typically HSS or cobalt and are suitable for general-purpose drilling in various metals.

Split-Point Drill Bits

Many HSS and cobalt drill bits feature a split-point tip. This design eliminates the need for a pilot hole by preventing the bit from "walking" on the material surface, making starting easier and more precise, especially on rounded surfaces.

Annular Cutters (Hole Saws)

Annular cutters, often referred to as hole saws, are specialized tools that cut a clean, burr-free hole by only cutting the periphery of the hole, leaving a solid slug in the center. They are highly efficient for drilling large-diameter holes in metal, producing less waste and requiring less power than twist drills.

Masonry Drilling Bits

Masonry bits are designed to withstand the abrasive nature of concrete, brick, and stone.

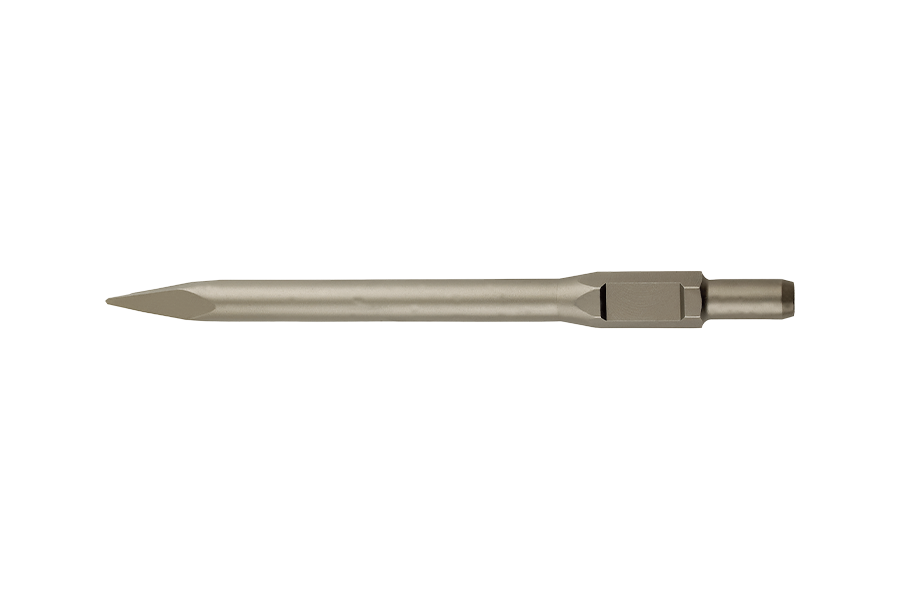

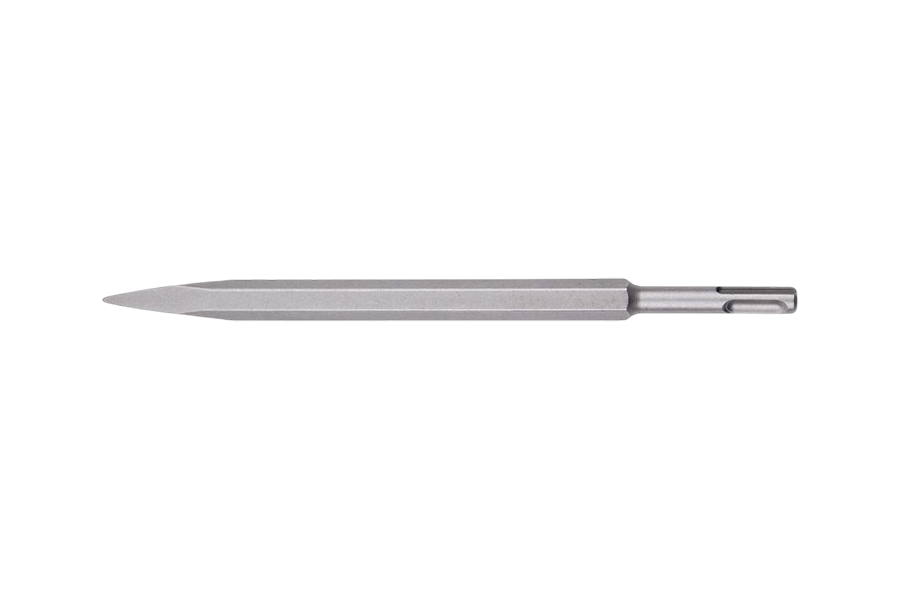

Carbide-Tipped Masonry Bits

Carbide-tipped masonry bits are characterized by their brazed-on carbide tips and often have a wider, more blunt cutting edge than metal or wood bits. They are used with hammer drills, which provide a pounding action in addition to rotation, to pulverize the masonry material. They are essential for drilling into concrete, brick, mortar, and stone.

Specialty Drill Bits

Beyond the primary categories, several specialized bits cater to unique drilling challenges.

Tile and Glass Bits

Tile and glass bits often feature a spear-point carbide tip, designed to cut cleanly through brittle materials like ceramic tile, glass, and porcelain without cracking or chipping. They should be used at low speeds and with water as a coolant.

Step Drill Bits

Step drill bits resemble a cone with multiple cutting edges of increasing diameter. They are used for drilling multiple-sized holes in thin materials like sheet metal, plastic, and aluminum. They are excellent for deburring holes and can create perfectly round holes without distortion.

Countersink Bits

Countersink bits are used to create a conical recess in a material so that the head of a screw or bolt can sit flush or below the surface. They are essential for achieving a professional finish in woodworking and metalworking.

Installer Bits

Installer bits are extremely long, flexible drill bits often used for routing wires through walls and ceilings. They have a small hole near the tip for attaching a pull string.

Choosing the correct drill bit for the job is paramount for safety, efficiency, and the quality of the finished product. Always consider the material, the desired hole size and depth, and the type of drill being used to select the most appropriate bit.

English

English

中文简体

中文简体

Español

Español

عربى

عربى