In the vast and intricate world of manufacturing and material removal, few tools are as ubiquitous and fundamental as the drill bit. And among the myriad of designs and specialized applications, the "solid drill bit" stands out as a true workhorse, a testament to simplicity, strength, and precision. Often overlooked in favor of more complex or exotic cutting tools, the solid drill bit is the unsung hero that forms the foundation of countless products we use every day.

What is a Solid Drill Bit?

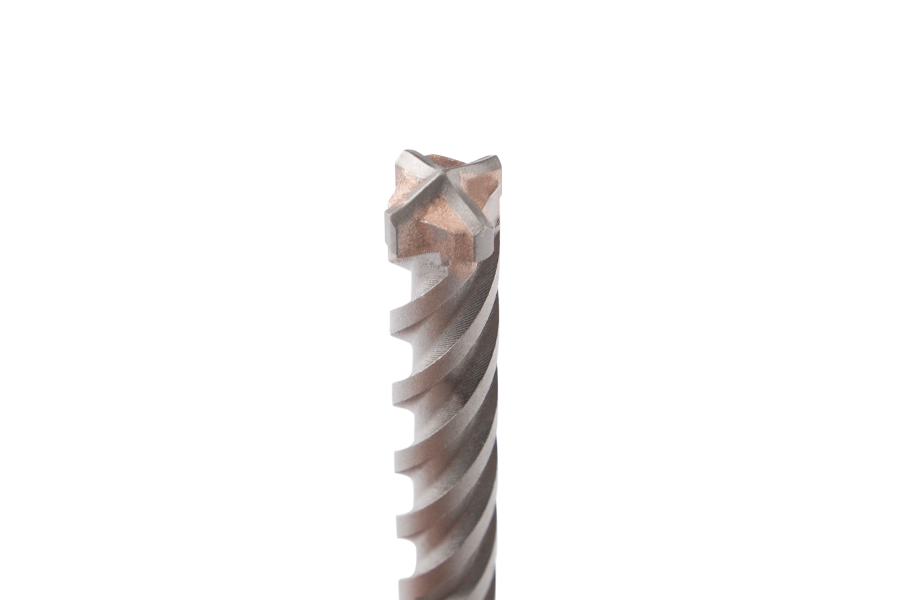

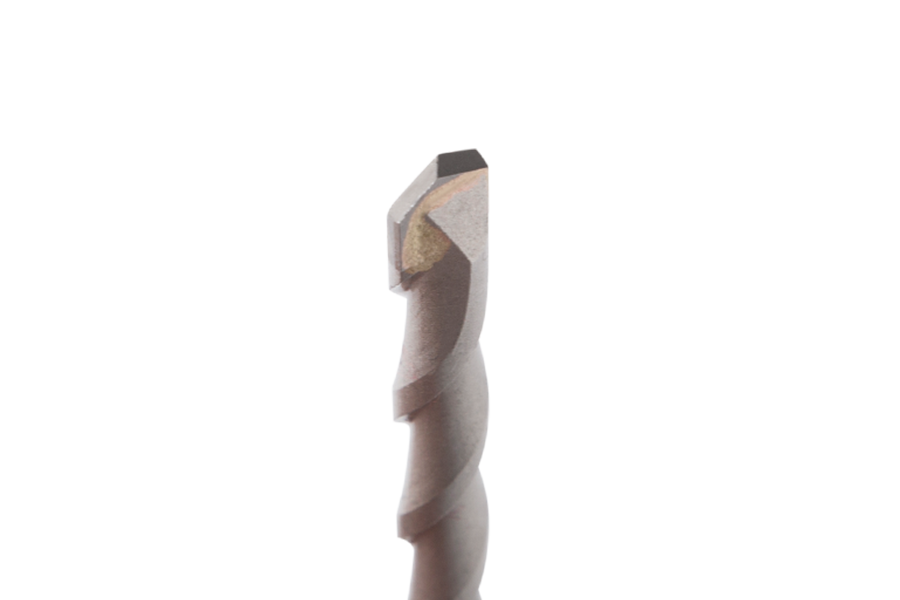

At its core, a solid drill bit is exactly what its name suggests: a single, monolithic piece of material, typically high-speed steel (HSS), cobalt alloy, or solid carbide, that is precision-ground to create cutting edges. Unlike indexable drills which utilize replaceable inserts, or spade drills that have a separate cutting head, the solid drill bit's integrity lies in its unified construction. This inherent simplicity is a major contributor to its strengths.

Key Characteristics and Advantages:

The solid construction of these drill bits offers a number of significant advantages that make them indispensable in various machining operations:

Exceptional Rigidity and Stability: Because the drill bit is one solid piece, it exhibits superior rigidity compared to multi-component tools. This minimizes deflection and vibration during drilling, leading to more accurate hole geometries, better surface finishes, and reduced tool wear.

Precision and Accuracy: The ability to grind precise cutting geometries directly onto the solid body allows for very tight tolerances and consistent hole quality. This is crucial in applications where precise hole sizing and positioning are paramount.

Versatility: Solid drill bits are incredibly versatile. They can be used to drill a wide range of materials, from soft plastics and aluminum to tough steels, stainless steels, and even hardened alloys, depending on the material of the drill bit itself and its coating.

Cost-Effectiveness (in many scenarios): While a high-quality solid carbide drill bit might have a higher initial cost than an insert for an indexable drill, their regrindability and longer tool life in appropriate applications can lead to lower overall cost per hole.

Excellent Chip Evacuation: The flutes, which are ground into the solid body, are designed to efficiently evacuate chips from the cutting zone. This prevents chip packing, reduces heat buildup, and minimizes the risk of tool breakage.

Regrindability: High-quality solid drill bits, especially those made from HSS or cobalt, can often be reground multiple times, extending their lifespan and further reducing tooling costs. Solid carbide drills can also be re-sharpened, though it requires specialized equipment.

Materials of Construction:

The performance of a solid drill bit is heavily dependent on the material from which it is made:

High-Speed Steel (HSS): A common and economical choice, HSS drills are suitable for general-purpose drilling in softer materials and non-ferrous metals.

Cobalt (HSS-E): An alloy of HSS with added cobalt, these drills offer improved hardness, wear resistance, and heat resistance, making them ideal for drilling harder materials like stainless steel and some alloys.

Solid Carbide: The pinnacle of solid drill bit technology, solid carbide drills offer exceptional hardness, rigidity, and wear resistance. They are capable of drilling at much higher speeds and feeds, delivering superior accuracy and surface finish in even the toughest materials, including hardened steels and exotic alloys. Their brittleness, however, requires more rigid machine setups.

Applications Across Industries:

Solid drill bits are fundamental to almost every manufacturing sector:

Automotive: Drilling holes for fasteners, engine components, chassis assembly.

Aerospace: High-precision drilling in specialized alloys for aircraft structures and engine parts.

Medical: Creating precise holes in medical devices and instruments.

Mold & Die: Drilling cooling channels and ejector pin holes in molds.

General Machining: Countless applications in job shops, fabrication, and repair.

Conclusion:

While advancements in cutting tool technology continue to push the boundaries of what's possible, the solid drill bit remains an indispensable tool. Its elegant simplicity, combined with its inherent strength, precision, and versatility, ensures its continued role as the backbone of countless drilling operations worldwide. From the smallest hobbyist workshop to the most advanced aerospace manufacturing facility, the solid drill bit continues to prove its worth, quietly and efficiently shaping the world around us, one perfectly drilled hole at a time.

English

English

中文简体

中文简体

Español

Español

عربى

عربى