Masonry Drill Bit (General Purpose)

What it is:

A broad category of drill bits designed for drilling into various types of masonry materials. These are the most common type you'll find for home improvement or light construction.

Key Characteristics:

Materials Best Suited For:

Brick: Both solid and hollow.

Concrete Blocks / Cinder Blocks: Relatively softer and more porous than poured concrete.

Mortar Joints: The material between bricks or blocks.

Stucco / Plaster: Softer, external wall finishes.

Lightweight Concrete: Such as screed or some pre-cast panels that aren't heavily reinforced.

Natural Stone (Softer Varieties): Like sandstone or limestone.

Tip Design:

Typically features a carbide-tipped head. This carbide is a very hard material (often tungsten carbide) brazed onto a steel shank.

The tip usually has a chisel-like or spade-like shape. This design is effective at pulverizing the relatively less dense materials.

Shank:

Often has a round shank for use in standard chucks (like those on a regular hammer drill or even a rotary drill).

Recommended Drill:

Can be used with a standard rotary drill for very soft materials or pilot holes.

Hammer drill is highly recommended and almost always necessary for efficient drilling into most masonry, as the hammering action helps to break up the material.

Durability: Good for its intended purpose, but constant use on very hard materials (like reinforced concrete) can quickly wear them out or cause them to overheat.

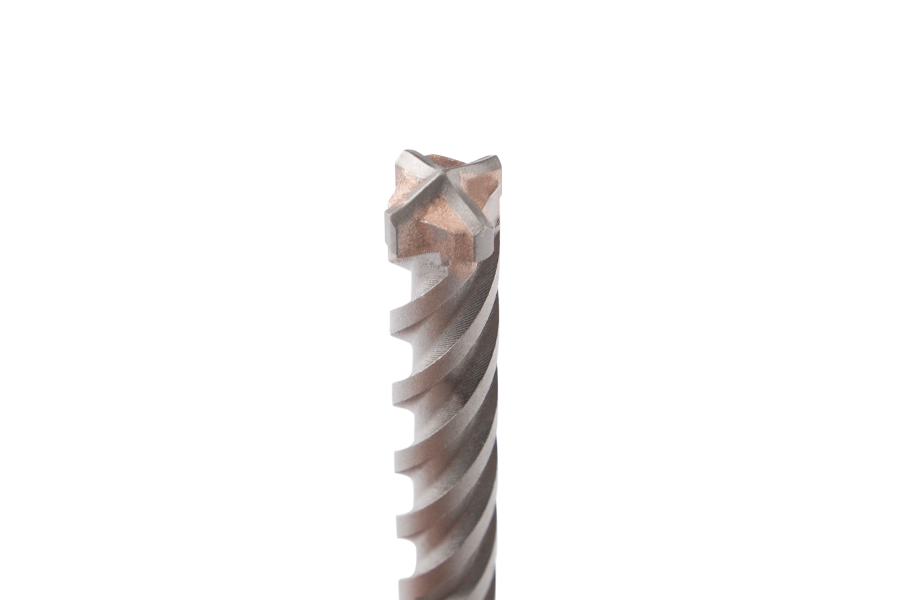

Concrete Drill Bit (Specialized / Heavy-Duty Masonry Bit)

What it is:

While technically a type of masonry drill bit, a "concrete drill bit" refers to a more robust, specialized version specifically engineered to handle the extreme hardness and abrasive nature of poured concrete, especially when it contains steel reinforcement (rebar).

Key Characteristics:

Materials Best Suited For:

Poured Concrete: High-strength, dense concrete.

Reinforced Concrete (with Rebar): Designed to resist the impact of hitting steel reinforcement without shattering.

Hard Natural Stone: Such as granite, basalt, or slate.

Asphalt: Dense road surfaces.

Tip Design:

Features a highly robust and often larger carbide tip compared to general masonry bits.

The carbide itself may be a higher grade, or the bonding (brazing) to the steel shank is stronger.

May have multiple cutting edges (e.g., a "quad-cutter" or "X-head" design). This provides more contact points, faster drilling, better dust removal, and resistance to jamming if it hits rebar.

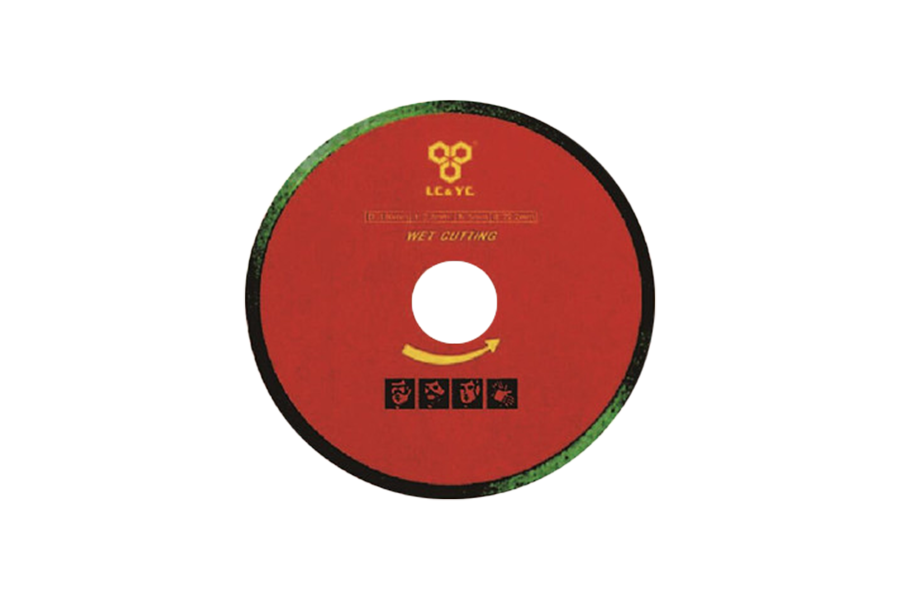

For extreme applications, some high-performance concrete bits may even incorporate synthetic diamond segments on the cutting edge for ultimate hardness and abrasion resistance.

Shank:

Often features a specialized shank system like SDS (Slotted Drive System), SDS-Plus, or SDS-Max. These shanks fit into rotary hammers or dedicated hammer drills, providing a more secure connection, better power transfer, and allowing the bit to slide back and forth for optimal hammering action without slipping. This also prevents damage to the drill's chuck.

Recommended Drill:

Almost exclusively used with a heavy-duty hammer drill or, more commonly, a rotary hammer drill. The powerful hammering action of these tools is essential for breaking down dense concrete.

Durability: Significantly more durable and heat-resistant than general masonry bits. They are designed to withstand the high friction, impact, and heat generated when drilling through concrete and potentially steel rebar.

Analogy:

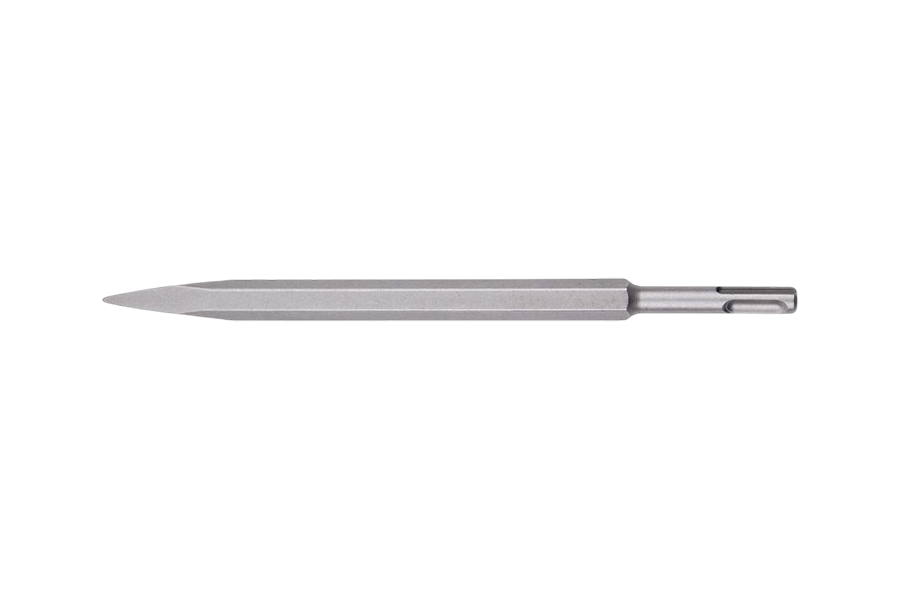

Think of it like this:

A general masonry drill bit is like a robust chisel – good for chipping away at most stone and brick.

A concrete drill bit is like a specialized jackhammer bit – designed for heavy-duty demolition and pulverization of the hardest, densest materials, and built to withstand striking metal.

When to Choose Which:

Use a general masonry bit when: You're drilling into standard brick, concrete block, mortar, stucco, or softer natural stone for tasks like hanging pictures, installing shelves, or routing cables.

Use a specialized concrete drill bit when: You're drilling into poured concrete (especially if it might be reinforced), very hard stone, or for any heavy-duty anchoring where precision and durability are critical. Always pair it with the appropriate SDS-compatible hammer drill or rotary hammer for best results and tool longevity.

English

English

中文简体

中文简体

Español

Español

عربى

عربى