While often used interchangeably in casual conversation, "SDS Plus" and "hammer drill" refer to distinct aspects of drilling technology. A hammer drill is atypeof drill that incorporates a hammering or percussive action in addition to rotation, specifically designed for drilling into hard materials like concrete, brick, and masonry. SDS Plus, on the other hand, refers to a specific chuck and shank system that is commonly found on aparticular classof powerful hammer drills, often called rotary hammer drills.

Let's break down the differences:

Hammer Drill (Standard)

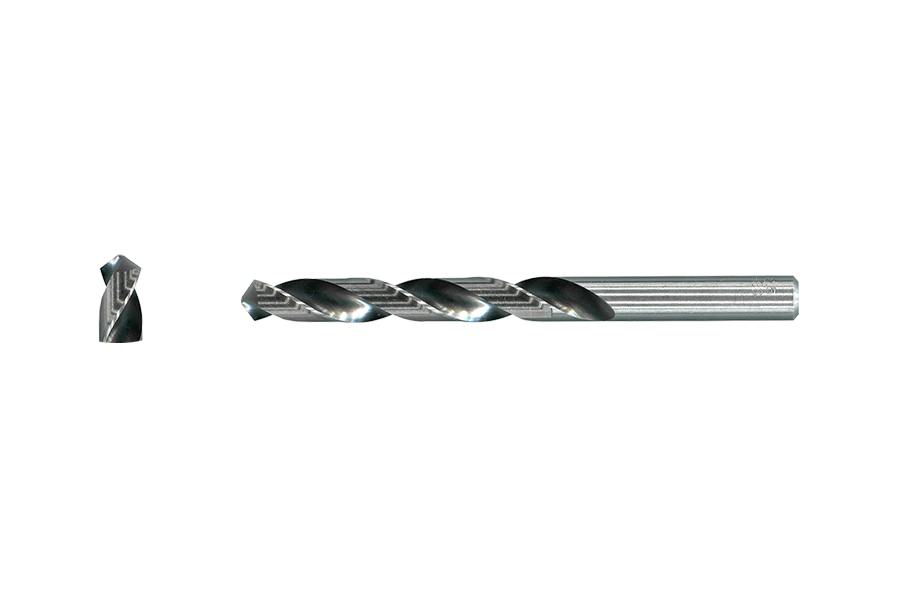

A standard hammer drill resembles a regular drill but includes a special mechanism that allows the drill bit to rapidly "hammer" or "peck" forward as it rotates. This percussive action helps to break up the material being drilled, making it easier for the bit's rotating flutes to remove debris.

Key Characteristics:

-

Chuck Type: Typically uses a keyless chuck, similar to a standard drill, which grips the bit tightly. Bits for these drills usually have smooth round shanks or hexagonal shanks.

-

Hammering Mechanism: Often employs a "clutch" mechanism with two ribbed discs that engage and disengage as the drill rotates, creating the hammering action.

-

Impact Force: Generally provides less impact energy compared to SDS Plus rotary hammers.

-

Versatility: Many standard hammer drills have a "drill-only" mode, allowing them to function as regular drills for wood, metal, and other non-masonry materials.

-

Applications: Ideal for lighter-duty masonry work, such as drilling small to medium-sized holes in brick, mortar, cinder blocks, or for occasional concrete drilling for anchors or small fixings. They offer more control for tasks requiring precision in softer masonry.

SDS Plus (Rotary Hammer Drill)

SDS Plus refers to the Slotted Drive System Plus chuck and corresponding bit shank design. This system was developed by Bosch to provide a more efficient and robust way to transfer hammering energy from the drill to the bit, particularly for heavy-duty concrete and masonry applications. Drills that use SDS Plus bits are often called rotary hammer drills.

Key Characteristics:

-

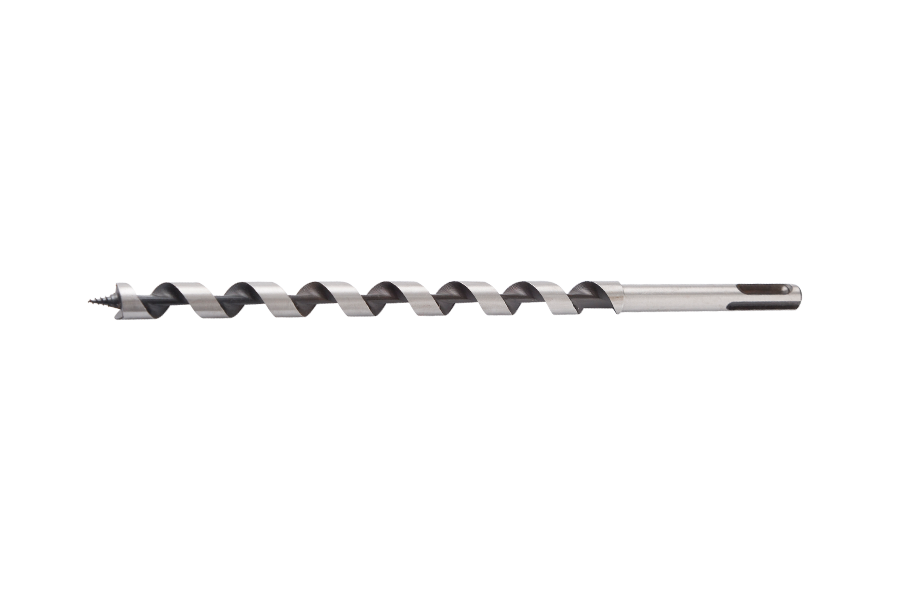

Chuck Type: Features a specialized SDS Plus chuck with grooves that allow the bit to slide back and forth like a piston while still being held securely for rotation. This "floating" action means the hammer mechanism directly impacts the back of the drill bit, not the chuck, leading to much more efficient energy transfer.

-

Shank Design: SDS Plus bits have a 10mm shank diameter with four grooves (two open and two closed) that lock into the SDS Plus chuck.

-

Hammering Mechanism: Uses a more sophisticated pneumatic (air-piston) hammer mechanism, which delivers significantly higher impact energy (joules) and blows per minute (BPM) than a standard hammer drill.

-

Power and Efficiency: SDS Plus drills are considerably more powerful and faster at drilling into hard concrete, stone, and reinforced concrete. The direct impact on the bit results in superior drilling performance for challenging materials.

-

Modes of Operation: Most SDS Plus rotary hammers offer at least three modes:

-

Rotary Drilling: For drilling into wood, metal, or plastics without the hammering action.

-

Hammer Drilling: Combines rotation and hammering for concrete, masonry, and stone.

-

Chiseling (Hammer-Only): Stops rotation, allowing the tool to be used with chisel bits for light demolition, tile removal, or breaking up concrete.

-

-

Applications: Essential for professional construction and renovation work, including:

-

Drilling large diameter holes in concrete for rebar or anchors.

-

Breaking up concrete or masonry for demolition.

-

Chiseling tasks like removing old tiles or mortar.

-

Installing heavy fixtures in concrete.

-

The Core Distinction

The fundamental difference lies in their chuck design and the efficiency of their hammering mechanism:

-

A standard hammer drill uses a conventional chuck and a less powerful, gear-driven hammering action, making it suitable for lighter masonry tasks.

-

An SDS Plus rotary hammer uses a specialized SDS Plus chuck and a powerful pneumatic hammering mechanism that directly impacts the bit, making it far superior for heavy-duty concrete and masonry drilling and chiseling.

In essence, while all SDS Plus drills are a type of hammer drill (specifically, a rotary hammer drill), not all hammer drills are SDS Plus. If you're tackling serious concrete work, an SDS Plus rotary hammer is the tool of choice. For occasional, lighter drilling into brick or mortar, a standard hammer drill might suffice.

English

English

中文简体

中文简体

Español

Español

عربى

عربى