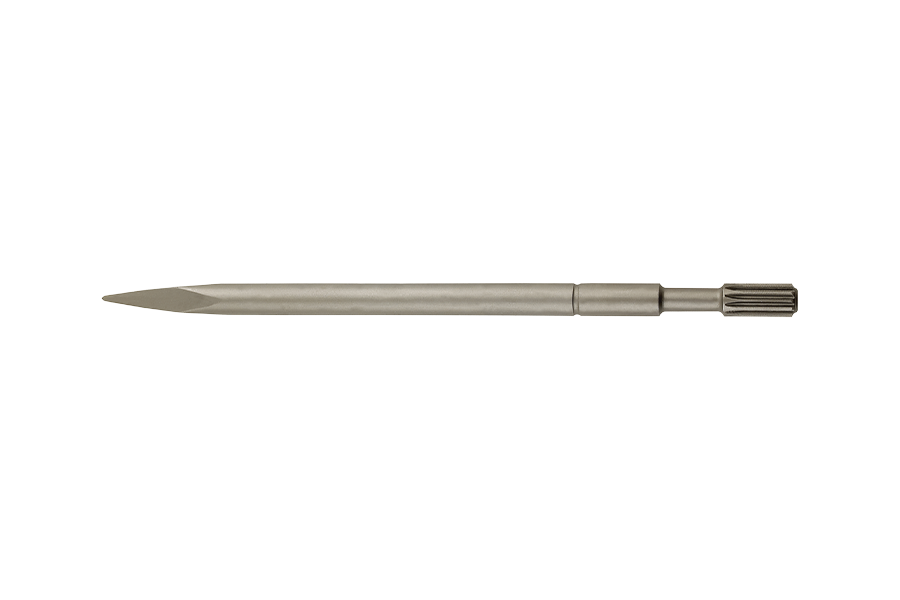

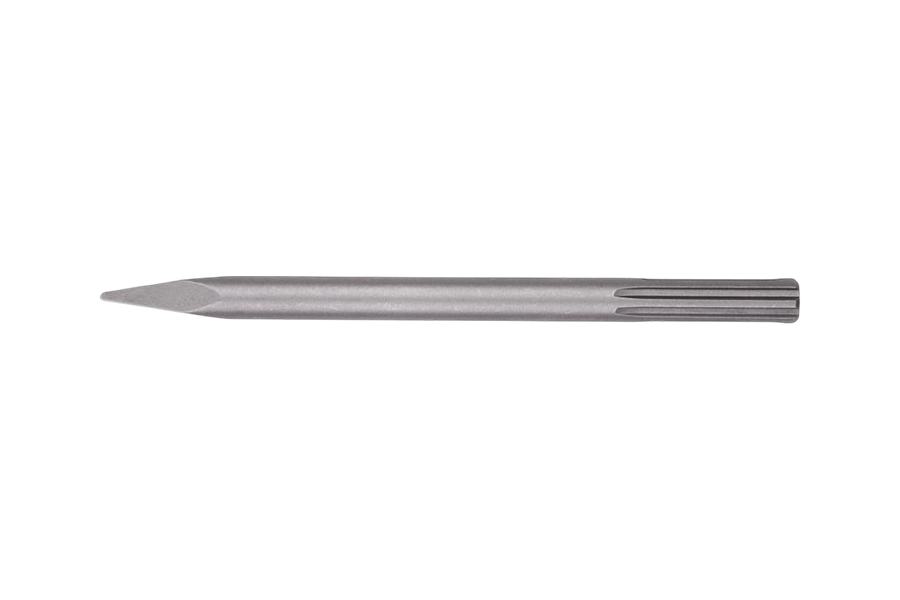

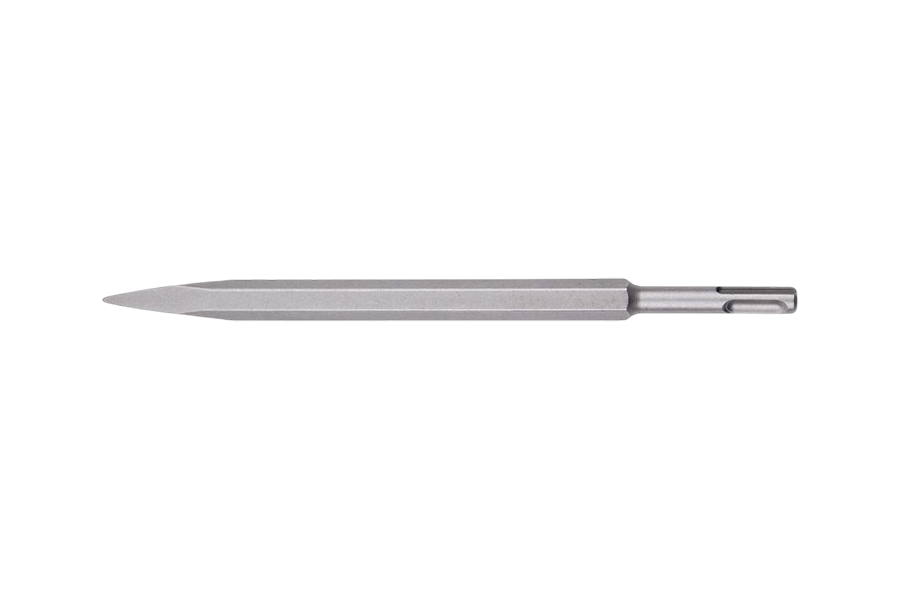

When it comes to tackling tough materials like concrete, masonry, or stone, a hammer drill bit is an indispensable accessory in any toolkit. Designed specifically for use with hammer drills, these bits combine the functionality of a traditional drill bit with a powerful percussive action that allows them to penetrate hard surfaces efficiently and effectively.

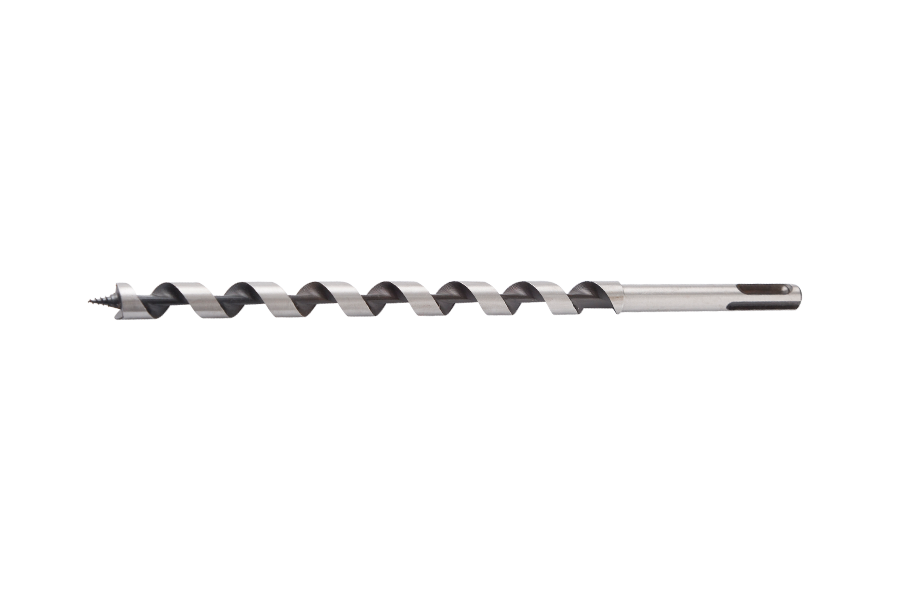

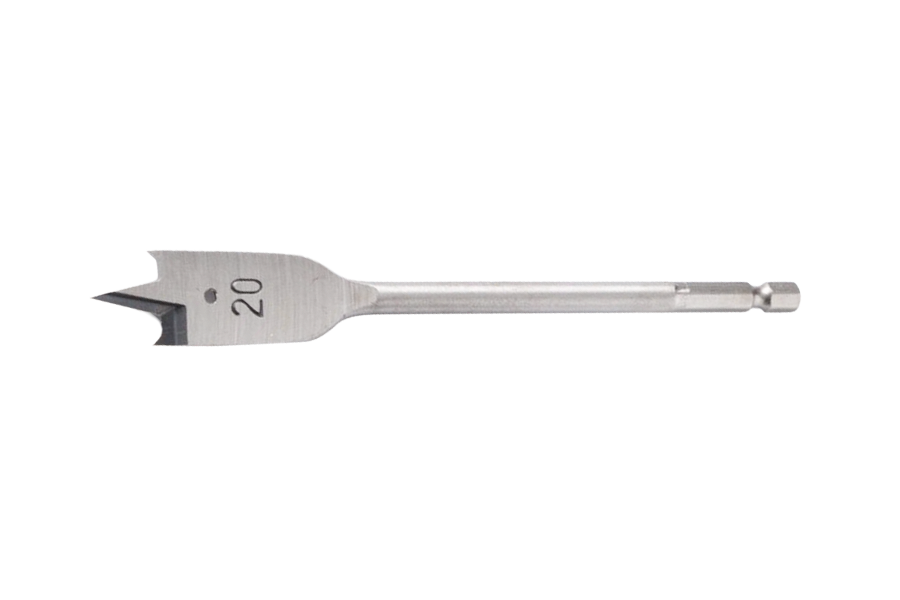

A hammer drill bit, also known as a rotary hammer bit or masonry drill bit, is engineered to withstand the intense impact and rotational force exerted by hammer drills. Unlike standard drill bits, which rely solely on rotational movement, hammer drill bits deliver a rapid hammering motion that breaks up hard materials as the bit rotates, enabling faster and deeper drilling.

Key Features of Hammer Drill Bits

Hammer drill bits typically feature a tough, carbide tip that can endure abrasive surfaces without dulling quickly. The shaft is often reinforced to resist bending and snapping during heavy use. These bits come in various sizes and lengths to accommodate different drilling needs, from small anchor holes to large diameter boreholes.

Applications of Hammer Drill Bits

The primary use of hammer drill bits is drilling into hard materials such as concrete blocks, bricks, stone, and other masonry surfaces. They are essential for installing anchors, rebar, electrical conduit, plumbing pipes, and other fixtures in construction and renovation projects. Because of their durability, these bits also perform well in outdoor tasks involving stonework and paving.

Choosing the Right Hammer Drill Bit

Selecting the appropriate hammer drill bit depends on the material and the size of the hole you need. Carbide-tipped bits are the best choice for concrete and masonry due to their hardness and resistance to wear. For softer materials, a standard masonry bit might suffice, but for demanding projects, investing in high-quality rotary hammer bits will improve efficiency and bit lifespan.

Maintenance and Care Tips

To maximize the lifespan of your hammer drill bit, it’s important to keep it clean and inspect it regularly for signs of wear. Using the correct drilling speed and applying moderate pressure helps prevent overheating and premature damage. When drilling through reinforced concrete, specialized bits designed for rebar cutting can make the process smoother.

English

English

中文简体

中文简体

Español

Español

عربى

عربى